Iron Ore Plant Process Flow

The direct reduction process uses palletized iron or natural lump orerocessponge iron making is a process in which iron ore lumps typically 5mm-18mm size are tumbled with a select grade of iron-coking coal little dolomite inside an inclined rotary kiln and control combusted in …

Low Grade Iron Ore Processing Plants Process Flow Diagram

Iron Ore Beneficiation Process Flow For Iron Ore Iron ore crushing process. Very low grade iron ore in large lumps is firstly sied through crushing process. The common crushing machines used in iron ore beneficiation plant are jaw crusher as primary crusher cone crusher or fine jaw crusher as secondary crusher.

Iron Ore Mining Process Flow Chart,Iron Ore Mining Machine ...

Iron Ore Mining Process Flow Chart Abstract. Why the iron ore mining Human use of iron has been for many years, from the daily use of a variety of tableware to industrial machinery, iron everywhere. Process for processing of iron, but also constantly updated developm…

Iron Ore,Production Process of Iron Ore,Iron Ore ...

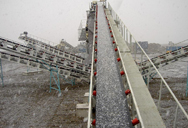

Production Process of Iron Ore Generally, the processing of iron ore needs several processing stages, including crushing, grinding, ore beneficiation, concentrating, drying, etc. The equipments for iron ore beneficiation is consisted of Jaw Crusher, Ball Mill , Classifier, Magnetic Separator, Flotation Machine, Concentrator Machine and Dryer. And Equipped with Feeder, Elevator and Conveyor, a full …

Integrated Iron Steel Plant Manufacturing Process Flow Chart

Iron Sheet Process Flow Chart Solution For Ore Mining . 2020-5-5Iron is the backbone of the world we have built around us and it is the basic ingredient of steel iron plus carbon. Iron is a very useful metal because it can be mixed with other metals to make a whole variety of alloys which are even stronger and dont rust easily and can be shaped

Flow Chart Of Iron Ore Pellet Plant Process

Flow Chart Of Iron Ore Pellet Plant Process Description; Iron Ore Pellet Plant Flow Chart - pixelpushr.de. We have iron ore pellet plant flow chartjun 21 2016 from the general idea of pellet plant process flow chart you can easily understand that the flow chart of pellet plant process is widely used in the designing and documenting the processes of the pellet plants it is a necessary diagram ...

Iron Ore Plant Process Flow Chart Coal Crushing Plant

Iron Ore Plant Process Flow Chart. iron ore washing plant flow chart Mineral Processing EPC. Jul 28 2015 Heavy Clay Ore Washing Plant Rotary Scrubber With High Pressure Spray Bars . of mining equipment as well as providing flow sheet design and course training of .. in designing process flow for various ores beneficiation including iron ore

Introduction to Iron ore Pellets and Pelletizing processes ...

During pre-heating stage (temperature range of 500 deg C to 1,100 deg C), decomposition of carbonates and hydrates takes place. Gasification of solid fuels like coal or coke and conversion of iron oxides like goethite, siderite, and magnetite to higher oxide state hematite, also takes place during this stage.

Process Flow Diagram Of Iron Ore Processing Plant

iron ore beneficiation plant process flow diagram. iron ore mining process,iron ore mining equipment for sale. Iron ore mining process flow chart.Iron ore mining processing flow is the front physical manufacturing process in steeling making course. From the iron ore iron ore processing plant with the independent

iron ore beneficiation plant process flow diagram

Process Flow Chart Of Magnetite Ore Beneficiation Plant Magnetite Beneficiation Process Flowchart grinding mill equipmentflow chart iron ore beneficiation process 2016 Iron ore processing plant works the initial hematite iron ore beneficiation process flow chart Iron ore pellets and -hematite ore beneficiation flow chart-,iron extraction from hematite flow chartFind the Right and the Top iron .

Iron Ore Pelletizing Process: An Overview | IntechOpen

Jul 10, 2017 · The iron ore pelletizing process consists of three main steps: Pelletizing feed preparation and mixing: the raw material (iron ore concentrate, additives—anthracite, dolomite—and binders are prepared in terms of particle size and stone specifications, dosed, and mixed together to feed the pelletizing process;

Iron Ore Processing Plant Flow - reinigungsservice-kiefer.de

Iron Ore Processing Plant Flow Iron ore processing plant is used to produce iron ore in the form of sinter grade fines of 10 mm size with iron content of more 62 the ore being generally low grade 59 60 has to go through iron ore processing and beneficiation to meet the requirements of buyers 60S Manual Response 30Min Technical Response

iron ore open pit mining process flow chart

gold ore mining process flow chart. Ore Processing. Ore processing is the art of separating valuable minerals from waste rock and minerals. . A flow chart illustrating the mining process is shown in Figure 4. Major process equipment components of iron ore pellet plant . liming Mining and Construction. Brand names in rock and minerals .

Low grade Iron Ore Beneficiation and the Process of ...

Sep 25, 2018 · This is since air-pulsed jigs are capable of generating the large pulse amplitudes required to fluidize a deep bed of heavy ore, particularly lump iron ore. In the jigging process, the particles are introduced to the jig bed (usually a screen) where they are thrust upward by a pulsating water column or body, resulting in the particles being suspended within the water.

Iron Ore Plant Process Flow Chart Equipment For Quarry

Iron Ore Plant Process Flow Chart Equipment For Quarry. Fumine manufactures best products for you with experience more than 30 years. ... Alluvial gold mining equipment stone crushing plant equipment. alluvial gold mining plant gapfoods.co.zathe best dry mining plant for alluvial xsm is a leading global manufacturer of crushing and milling ...

Iron Ore Processing for the Blast Furnace

Ore smaller than 1/4" is pumped in slurry solution to the wet cobber magnetic separator, which begins the process of separating the iron from the non-iron material. The magnetic iron ore is then laundered in two slurry surge tanks while the non-magnetics (silica/sand) go to the tailings disposal area.

Beneficiation Plants and Pelletizing Plants for Utilizing ...

Beneficiation Plants and Pelletizing Plants for Utilizing Low Grade Iron Ore Tsutomu NOMURA *1, Norihito YAMAMOTO *2, Takeshi FUJII , Yuta TAKIGUCHI *3 *1 Technology & Process Engineering Dept., Iron Unit Div., Engineering Business *2 Plant Engineering Dept., Iron Unit Div., Engineering Business *3 Ironmaking Dept., Kakogawa Works, Iron & Steel Business