Calculate and Select Ball Mill Ball Size for …

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize “just in case”. Well, this safety factor can cost you much in recovery and/or mill liner wear and ...

Ball Mills - an overview | ScienceDirect Topics

where db.max is the maximum size of the feed (mm), σ is the compression strength (MPa), E is the modulus of elasticity (MPa), ρ b is the density of material of balls (kg/m 3), and D is the inner diameter of the mill body (m). Generally, a maximum allowed ball size is situated in the range from D /18 to D /24.

Ball mill - Wikipedia

The ball mill can grind ores and other materials either wet or dry. There are two kinds of ball mill, grate type and overfall type, due to different ways of discharging material. Many types of grinding media are suitable for use in a ball mill, each material having its own specific properties and advantages. Key properties of grinding media are size, density, hardness, and composition.

Effect of ball and feed particle size distribution on …

01.06.2018 · The availability of a ball size for a particular feed size ensures breakage occurs at a faster rate. The 10 mm ball size is unable to nip the large particle size hence the breakage rate is slower. For a finer feed, the 20 mm + 10 mm binary mix is able to break the feed at a faster rate. Download : Download high-res image (344KB)

feed size ball mill - grill-restaurant-zagreb.de

Silica glass was ground with a ball mill while varying the feed size and ball diameter, and measured K1. (3) An experimental equation was obtained by expressing K1 as a function of feed size and ball diameter. 2. Sample Used and Experimental Method. Get Price. Top 5 product-specific milling technologies used … Impact and attrition size-reduction methods include air classifying mills, pin ...

Ball Mill Loading - Dry Milling - Paul O. Abbe

Ball Mill Loading - Dry Milling. Ball Mill Loading (dry milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct amount of product. Charging a Dry Mill – The general operation of a grinding mill is to have the product impacted between the balls as they tumble. If ...

dry ball mill feed size - sameaworkshop.co.za

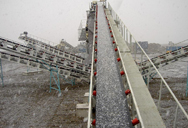

dry ball mill feed size. Home; dry ball mill feed size ; Get Price Here.... Ball Mill. Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two… Get Price Here.... Belt Conveyor. ASM delivers the world’s most comprehensive range of Heavy-duty conveyor belts. Base on more than 30… Get Price Here.... BWZ Heavy Duty Apron Feeder. BWZ series ...

Wet and dry grinding of coal in a laboratory-scale …

01.01.2020 · The efficiency of size reduction is influenced by a number of variables including the mill speed, ball size, filling rate, feed size distribution, pulp density, coal rank , the mode of grinding (wet or dry), material hardness, and dissemination features [, , , , , , , , ]. The mode of grinding, wet or dry, has significant differences in grinding kinetics and the properties of the ground ...

Ball Milling | Material Milling, Jet Milling | AVEKA

In ball milling, the desired particle size is achieved by controlling the time, applied energy, and the size and density of the grinding media. The optimal milling occurs at a critical speed. Ball mills can operate in either a wet or dry state. While milling without any added liquid is commonplace, adding water or other liquids can produce the finest particles and provide a ready-to-use ...

Feed Size VS Ball Size - Grinding & Classification ...

To participate in the 911Metallurgist Forums, be sure to JOIN & LOGIN Use Add New Topic to ask a New Question/Discussion about Grinding. OR Select a Topic that Interests you. Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent). Using Add Reply allows you to Attach Images or PDF files and provide a more complete input. Use Add Comment = to comment on someone else’s ...

Wet Ball Milling Vs Dry Ball Milling | Orbis …

27.06.2019 · Particle Size Reduction Milling the powder in the wet or dry state produces different results. Wet ball milling processes produces smaller particles, compared to dry ball milling process. Introduction Of Active Surface Media Wet ball milling allows easy introduction of surface active media having to do with the reduction of the required energy for the inhibition of aggregation of fine ...

Ball mills - liming

First, a Jar Mill grindability test requires a 5 lb. (2 kg) sample and produces a direct measured specific energy (net Hp-hr/t) to grind from the design feed size to the required product size. The second test, a Bond Work Index determination, results in a specific energy value (net Hp-hr/t) from an empirical formula.

Ball Mill - RETSCH - powerful grinding and …

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications.

dry dry chute feeder ball mill gear - kaiserhof …

Scoop Feeders for BallRod Mills are made in various radius sizes. Standard scoops are made of cast iron and for the 3 size a 13 or 19 feeder is supplied, for the 4 size a 30 or 36, for the 5 a 36 or 42, and for the 6 a 42 or 48 feeder. Live Chat 「Ball Mills」 CERAMIC LINED BALL MILL. Ball Mills can be supplied with either ceramic or stone linings for wet or dry grinding, for continuous or ...

Ball Mill Media Uk- EXODUS Mining machine

The ball mill is a tumbling mill that uses steel balls as the grinding media the length of the cylindrical shell is usually 115 times the shell diameter figure 811the feed can be dry with less than 3 moisture to minimize ball coating or slurry containing Ball Mill Media Uk : [email protected]

THE OPTIMAL BALL DIAMETER IN A MILL

Investigations were carried out in a laboratory ball mill having the size of DxL= 160x200 mm with a ribbed inside surface of the drum. The mill ball loading was 40% by volume, the rotation rate was equal to 85% of the critical speed. Balls were made from steel: S4146, extra high quality, having hardness 62 ± 2 HRC according to Rockwell.