flow diagram for coal tar plant

flow diagram for coal tar plant, Coal Tar Pitch Process Flow Diagram, process crusher, mining Coal Tar Pitch Process Flow Diagram 100 Views. Coal Tar Process Schematic - Nautiflex 2007612crude coal tar is a by product of the coking process.Coking is the process of heating coal in a reducing atmosphere and the offgas is collected and sent to the byproduct plant where various byproducts are ...

coal tar pitch process flow diagram afghanistan

Process Description 8 Process Flow Diagram 9 Plant Layout 10 Details of Plant & Machinery 11 Suppliers of Raw Materials , Cash Flow Statement 17 Projected Balance Sheet SYI services are: , Manufacturing Process of Coal Tar Pitch in Guatemala, Method For Production of Coal Tar, Method of Production of Coal Tar Pitch, Methods of Charcoal.

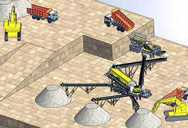

Flow diagram of coal to coal-tar-pitch process

Flow diagram of coal to coal-tar-pitch process (Public domain.) Thumbnail Medium Original. Detailed Description. Coal tar is a byproduct of the coking, liquefaction, or gasification of coal. Coal-tar pitch is the residue that remains after the distillation of coal tar.

Coal Process Flow Diagram

Coal mining process flow chart diagram coal mining ... Flow diagram of coal to coaltarpitch process public domain thumbnail medium original detailed description coal tar is a byproduct of the coking liquefaction or gasification of coal coaltar pitch is the residue that remains after the distillation of coal tar coal tar and coaltar pitch ...

Modeling of Oxidation Process of Coal Tar Pitch in ...

In this paper, a three-dimensional numerical model has been developed to study the process of oxidative weight increment of coal tar pitch in a rotating kiln. Based on the two-fluid method, the gas phase is modeled by realizable k - ε turbulent model and the solid phase is modeled by kinetic theory of granular flow. The dense gas-solid flow, heat transfer, and oxidation reaction for the bed ...

How is Crude Coal Tar Derived 1

Crude Coal Tar is a by product of the Coking process. Coking is the process of heating coal in coke ovens to drive volatile matter from it. Metallurgical Coke is used as a fuel and reducing ... Process Flow Diagram: Coke Oven Operation. b) Non-Recovery/Heat Recovery Coke Production:

Coal Tar and its Distillation Processes

The process of distillation gives a variety of valuable stone products. The residue of distillation is coal tar pitch, which is further processed into coal tar pitch of desired stone and physical properties. The primary objective of coal tar distillation process is to produce a number of tar acid products from the crude tar.

Coal-Tar Pitch

C.G. Cash, in Encyclopedia of Materials: Science and Technology, 2001. 2.9 Coal-tar Pitch Built-up Roofing. Coal-tar pitch membranes using coal-tar saturated organic felts is one of the oldest systems listed in Table 2.These systems perform very well historically, but are limited to very low slope applications and must be gravel surfaced because of the low viscosity of coal-tar pitch at normal ...

Product Stewardship Summary Coal Tar Pitch

Coal Tar Pitch (CAS number 65996-93-2) (EC number 266-028-2) Product Description Coal tar pitch is a black, viscous residue that remains after the distillation of coal tar. This process occurs at our plants and involves heating coal tar (the raw material used to produce coal tar pitch) in a still.

GRAPHITE MANUFACTURING PROCESS

Coal tar pitch, petroleum pitch or synthetic resins are used as binders. The powder preparation process is presented in the scheme below. ... The process, called graphitization, results in Crystallization of amorphous precursor carbon, which transforms into crystalline graphite.

Coal tar

Coal tar is a thick dark liquid which is a by-product of the production of coke and coal gas from coal. It has both medical and industrial uses. It may be applied to the affected area to treat psoriasis and seborrheic dermatitis (dandruff). It may be used in combination with ultraviolet light therapy. Industrially it is a railway tie preservative and used in the surfacing of roads.

Flow Measurement of Hot Pitch during Coal Tar …

Flow Measurement of Hot Pitch during Coal Tar Distillation. In one of the worlds largest coal tar refineries, the delivered raw material is distilled to obtain technical oils and aromatics, which serve as valuable basic materials for the dye and pharmaceutical industries.

Project Report on Coal Tar Pitch - Manufacturing …

Coal Tar Pitch Manufacturing Process Crude Coal Tar received from by-product coke oven plants is heated to temperatures up to 400oC in specially designed distillation stills. This removes moisture, Naphthalene, Light Creosote Oil and Heavy Creosote Oil from the Coal Tar. The resultant product is called Coal Tar Pitch.

Coal Tar Pitch

Coal tar pitch is produced from the processing of high temp. Coal tar by adopting the modern technology under the supervision of trained engineers and chemist.Coal Tar Pitch is available in two forms, i.e – Solid & Liquid. Recentaly, most of the Aluminium Industries have shifted to liquid coal tar pitch…

Pitch (resin)

Pitch is a viscoelastic polymer which can be natural or manufactured, derived from petroleum, coal tar, or plants. Various forms of pitch may also be called tar, bitumen, or asphalt.Pitch produced from plants is also known as resin.Some products made from plant resin are also known as rosin

Coal tar pitch and molasses blended binder for …

01-03-2017 · As illustrated in Fig. 1, the whole briquettes production process involves mixing coal fines with coal tar pitch and molasses, dispersing of xylene in water, blending them with the mixture of coal fines and blended pitch, briquetting the final blended material, drying or curing the green briquettes, carbonizing the cured briquettes and measuring the strength of the briquettes.

Typical Process Flow Diagrams (PFDs)

A typical process flow diagram (PFD) of such a vacuum distillation column is presented. Light vacuum gas Oil is sent to a hydrotreater and then to a ‘catalytic cracking’ unit to obtain smaller chain hydrocarbons. Heavy vacuum gas oil is also sent for cracking using hydrogen in a ‘hydrocracking unit’ to produce smaller chain hydrocarbons.

Coal Tar Pitch Roofing: Reference Page

25-06-2020 · Coal tar pitch is produced by distilling or heat-treating coal tar, which is a by-product of the production of coke or coal gas. It is solid (for all practical purposes) at room temperature. Coal tar pitch is melted on-site in an industrial kettle and applied to the roof as a hot liquid.

Phenol Production and Manufacturing Process

06-11-2007 · Phenol was first isolated from coal tar in the coking of coal, but the first commercial process was the sulphonation of benzene and subsequent fusion with caustic soda.. There are now three synthetic routes to phenol with cumene-based technology being the dominant process.Here, benzene and propylene are reacted to form cumene, which is oxidised to the hydroperoxide, followed …

Neptune Hydrocarbons | Coal Tar Pitch

The impregnating-grade coal tar pitch is a special type of coal tar pitch, which has a low content (0-3 %) of Quinoline Insolubles (QI), besides having lower values of softening point (SP), Toluene Insolubles (TI), coking yield and Specific Gravity (SG), compared to those of the binder-grade coal tar pitch.