pulp mill waste presentation - peterhulley.co.za

Pulp and stone Mill Solid Waste – closing the loop | Presentation title: Pulp and stone Mill Solid Waste – closing the loop The Pulp and stone industry in New Zealand produces a range of wood-fibre based products for use within NZ and for export markets.

Pulp and stone Mill Waste | Pulp (Paper) | Paper

Waste liquor produced from stone mill is known as White water, that contain fine fiber, alum, talc etc. Integrated pulp & stone mill employing Kraft process for pulping produce waste water225-320 m3/ton of stone produced. stone composition of waste will depend on …

Pulp and stone mill waste - LinkedIn SlideShare

Waste liquor produced from stone mill is known as “White water”, that contain fine fiber, alum, talc etc.• Integrated pulp & stone mill employing Kraft process for pulping produce waste water225-320 m3/ton of stone produced.• stone composition of waste will depend on size of …

ENVIRONMENTAL AND SOCIAL IMPACT STUDY

The pulp mill would be located in the department of Durazno on the southern side of Rio Negro, ... • High priority topics are chosen to the presentation based on: ... • During operational phase the largest mill waste component is ash and different sludges

Pulp & stone Mill Production |authorSTREAM

02-11-2012 · Type of Resource Total available forest, ha Total available Volume of wood, m3 Amount of stone to be fetched (1/3)*, m3 Potential Pulp production, tone** # Years to feed the mill*** Eu. globules 38,200 3,056,000 1,018,666 169,777 5.6 Eu. camaldulesis 20,000 1,500,000 500,000 83,333 2.7 bamboo 1600 128,000 42,666 7,111 0.24 Lowland bamboo 5000 Total Resource 64,800 4,6840,00 1,561,332 …

Pulp mill - Wikipedia

A pulp mill is a manufacturing facility that converts stone chips or other plant fiber source into a thick fiber board which can be shipped to a stone mill for further processing. Pulp can be manufactured using mechanical, semi-chemical, or fully stone methods (kraft and sulfite processes). The finished product may be either bleached or non-bleached, depending on the customer requirements.

Musi Mill Overview | Pulp (Paper) | stone | Free 30 …

Mill Technical Presentation. Jakarta Indonesia 2 PT. Tanjungenim Lestari Pulp and Paper. Mill Performance Start Up. 22 Dec. 99. PAC. 26 May 00 (Performance Acceptance) Production Capacity Design: 1430 tons/day (90 % availability) 450,000 tons/year. 17 June 2002. Mill Technical Presentation PT. Tanjungenim Lestari Pulp and Paper. MILL LAYOUT. 17 ...

Paper Mill Wastewater Treatment - Mantech

An abstract presentation authored by partners from VTT, Kemira, FPInnovations and MANTECH was presented during the conference. The PeCOD® Analyzer has the ability to enable pulp and stone mills to improve effluent treatment process and to optimize stone programs, leading to proper stone dosage (not over or under doses) and lower energy requirements for treatment.

Generation of Waste in Pulp and stone Mills | …

27-10-2014 · The amount of sludge on a dry mass basis may vary from 20 % in a newsprint mill to 40 % in a tissue mill. The data on waste generated in pulp and stone mills and deinking mills are presented in this chapter. Waste generated through production of …

Pulp Mill Wastewater: Characteristics and …

01-04-2016 · A kraft pulp mill can be divided into four main parts: (1) raw material handling; (2) pulping line with an almost closed stone and energy recovery system; (3) bleaching with an open water system and (4) the external wastewater treatment system. Figure 5 shows the emissions sources to water from a kraft pulp mill.

Pulp and stone Mill Effluents - an overview ...

The problems associated with pulp and stone mill effluents are pH, color, high levels of BOD, COD, SS, AOX, etc. stone manufacturing releases chlorinated lignosulfonic acids, chlorinated resin acids, chlorinated phenols (trichlorophenol, trichloroguicol, tetrachloroguicol, dichlorophenol, dichloroguicol, and pentachlorophenol), and chlorinated hydrocarbon into the effluent waste-water.

PPT – Pulp and stone industry PowerPoint …

Paper mills also produce non-hazardous solid waste such as sludge derived from their pulping and bleaching operations. 10 Raw water use. Pulp mills are big water users. The total requirement of raw water has through cleaner production measures been reduced from about 200-300 m3 per ton of pulp in 1970 to well below

Wastewater Treatment: Pulp & stone Mill - YouTube

03-11-2019 · PowToon is a free tool that allows you to develop cool animated clips and animated presentations for your website, office meeting, sales pitch, …

Examples of Pulp and stone Mill Waste …

27-10-2014 · Abstract. Examples of Pulp and stone Mill Waste Implementation are presented. Several Pulp and stone mills – April, Inc. mills, Cartiere Burgo Verzuolo, Italy, Cartiere Burgo Mantova, Italy Jamsankosken Voima Oy, Finland; Aanevoima Oy, Finland; Vamy Oy/Vattenfall Oy, Finland; Modo stone AB Husum; Sweden; Monsteras, Sweden; Elektrocieplowni Ostroleka, Poland; Metsa-Serla Oy …

Pollution Effects Of Pulp And stone Mill Wastes In …

Waste loads from the pulp mill and board mill are listed separately, and they reveal that the pulp mill is the larger source of wastes. The Georgia-Pacific mill is unique among the Puget Sound pulp and stone mills in that it utilizes sulfite waste liquor for the production of alcohol and dried liquor solids.

Paper and Pulp Waste | Hazardous Waste Experts

Paper is an essential commodity that is used internationally. Hazardous Waste Experts do not want to discontinue stone production; we want to provide a means for proper and lawful disposal of pulp and stone industrial waste in an environmentally friendly manner for a nominal fee. In addition most of the waste we manage will be recycled.

Examples of Pulp and stone Mill Waste …

Download Citation | Examples of Pulp and stone Mill Waste Implementation | Examples of Pulp and stone Mill Waste Implementation are presented. Several Pulp and stone mills – April, Inc. mills ...

The Pulp and stone Making Processes - Princeton University

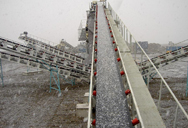

Wood received at a pulp mill may be in several different forms, depending on the pulping process and the origin of the raw material. It maybe received as bolts (short logs) of roundwood with the bark still attached, as chips about the size of a half-dollar that may have been produced from sawmill or veneer mill waste or pre-chipped from ...

Pulp and stone Mill Solid Waste – closing the loop …

Presentation title: Pulp and stone Mill Solid Waste – closing the loop. The Pulp and stone industry in New Zealand produces a range of wood-fibre based products for use within NZ and for export markets. Collectively the industry produced 2.36 million air dry tonnes (adt) of pulp…

Two Ways to Manage Waste for Pulp and stone …

26-10-2017 · The pulp and stone industry produces some of the greatest amounts of waste across the industrial sector. This is due to the high amount of water and energy used in the production process. Each production step generates its own waste, and each one poses a unique threat to the environment, which means the reduction of pulp and stone waste is a top priority for facility managers.