Mechanism Of Secondary Crusher - sport-hippique.nl

suijitupian80.jpg" /> Roller Crusher Mechanism- DYNAMIC Mining . Mechanism of size reduction 4 there are primary and secondary crushers a primary crusher reduces large particles into smaller sizes for further crushing by the secondary crusher examples of crushers include jaw crusher gyratory crusher and roll crusher a double roll crusher.

Crusher - Wikipedia

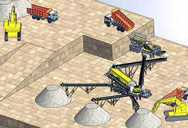

31-03-2003 · A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust.. Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiated.

stone crusher chute

Picture 6: repairing the primary crusher, boulder chute on right. Solutions Get Price; sand, gravel, and crushed stone on-the-job training modules. screening deck to secondary crushers, and is then returned to the primary . eventually form in chutes and skirt boards, …

crusher run stone trucks with chutes on them

truck chutes: feed chute Suppliers product chute Suppliers sand chute Suppliers...Crusher,Sand Making Machine,Ball Mill,Mineral Separator,Wood Machinery Tota... Free chat EP0094741B1 - Differential rate screening - Google

Primary Crusher - an overview | ScienceDirect Topics

Secondary coal crusher: ... Sometimes feeders are not used and instead feeding is achieved by chutes only. Factors like type of material to be handled, the storage method, and feed rate govern the type of feeder (Anon., 2014). In the primary crushing stage, the ore is …

P&Q University Lesson 7- Crushing & Secondary …

02-09-2019 · Cone crushers are similar to gyratory crushers in that they have a mantle that rotates within a bowl, but the chamber is not as steep. They are compression crushers that generally provide reduction ratios of 6-to-1 to 4-to-1. Cone crushers are used in secondary…

New Acland - Crusher & Chute Replacement - …

ENAP’s scope was awarded a project to undertake the site installation of new McLanahan Secondary Crusher for Plant Two at the New Acland Coal Mine. This scope also included the workshop fabrication of new chutes and structural modifications to suit the upgraded crusher.

Crushing Circuit Chutes and Screens - Wear …

Our crushing circuit contains primary crusher jaw , secondary cone crusher and tertiary cone crusher in which closed circuit with a double deck screen. the ore is quartz vein with average of Bond RWI 17.5khr/t and Bond BWI 16.8 kwhr/t. The chutes are made by our welding team but they dont have muc

New Acland Coal Secondary Crusher Replacement)

ENGINEERING APPLICATIONS – PROJECT DESCRIPTION New Acland Coal – Secondary Crusher Replacement Client: New Hope Coal, New Acland Coal Mine QLD Project: Replacement of Secondary Crusher, including fabrication of new chutes and structural modifications Duration: September 2013 to November 2013 Man Hours: Fabrication – 430 On-site Installation – 520

Secondary Crushing Equipment

The term “secondary crushing” has become well established and familiar through long usage; it applies to the crushing stage, either single or multiple, which follows immediately after the primary crusher, taking all or a portion of the product of the primary crushing stage as its feed. The term should not be used, as it sometimes is, to designate a particular type or size of crusher ...

Primary And Secondary Stone Crusher - praktijkwel …

Primary And Secondary Stone Crusher. Pq university lesson 7 crushing secondary breaking.By pq staff | september 2, 2019.They can be used for both virgin stone and recycled concrete and asphalt aggregates processing as a classic primary crusher for natural stone with an active double-deck grizzly, or as a recycling crusher with vibrating discharge chute and the crusher.

Crusher - an overview | ScienceDirect Topics

The secondary crusher is mainly used to reclaim the primary crusher product. The crushed material, which is around 15 cm in diameter obtained from the ore storage, is disposed as the final crusher product. The size is usually between 0.5 and 2 cm in diameter so that it is suitable for grinding. Secondary crushers are comparatively lighter in ...

Coal Chute Crusher - astridtillemans.nl

coal chute conveyor - Newest Crusher, Grinding … coal conveyor trash chutes - BINQ Mining . chute – ingilizce sözlük : ingilizce türkçe sözlük … pulverizer coal chute cleaning . pulverizer coal chute cleaning,pew series crusher is born with innovative significance.

Crushers Convor Chutes - scholmanloodgieters.nl

Rock crushers convor chutes Metal menace Pit Quarry Feb 28 2014 Erie metal detectors are primarily installed on conveyor belts carrying Front end loader bucket teeth rock bolts and even tools can find their way into the aggregate before entering transfer points chutes and crushers.

Secondary Crusher Impact Crusher - …

Secondary Crusher Impact Crusher. Jaw crusher jc series jaw crusher primary impact crusher secondary impact crusher cs cone crusher tyy lxpecondary impact crusher liming - crusherasiamecondary crusher,secondary crushing plant,clay secondary crushereconary crusher in liming is suitable for most of minerals such as clayecondary crusher machines.

ironore crusher - Scalepaint-Diorama`s

CZS High-Efficient Cone Crusher is a high-performance model optimized and improved on the basis of PY Series Spring Cone Crusher. It is widely used for secondary and fine crushing in the fields of mining, building materials, metallurgy and so on. Read more

小割圧砕機 (Secondary Crusher) G175 - YouTube

26-09-2017 · G175 is a single cylinder pulverizer, featuring NPK integrated exclusive booster, NPK pulverizers offer fast cycle time and high power. When the jaw meets re...

list of secondary crushers - wdb-transport.nl

List Out Types Of Secodary Crushers. list out types of secodary crushers Crusher - Wikipedia the free encyclopedia Industrial use Types of crushers Technology In the Dodge type jaw crushers progressively crushed until it is small enough to fall out through the gap used for primary or secondary.

secondary crusher design - ifoza.nl

Secondary Crusher Bin Discharge Chute Redesign - WEARX. The secondary crusher bin discharge chute was designed with skirt plates that ran parallel with the feeder belt This allowed rocks to jam and split the feeder belt Over 12 months 8 feeder belts were split at a cost of $1 million per belt. design of the secondary crusher iron ore ...

Chute Conveyor Primary Crusher - veteranen …

Chute Conveyor Primary Crusher. 2019-10-14jaw crusher for primary crushings we know, in crushing plant, there generally need a primary crusher and a secondary crusher in order to process the raw materials into required sizesaw crusher is the most commonly used primary crushing equipmente provides different types and models of jaw crusher, such as pe, pew and hj series jaw crusher.