Process In Manufacturing Cement And Aggregates

Process In Manufacturing Cement And Aggregates. The manufacturing process the manufacture of concrete is fairly simpleirst, the cement usually portland cement is preparedext, the other ingredientsaggregates such as sand or gravel, admixtures stone additives, any necessary fibers, and waterare mixed together with the cement.

Process In Manufacturing Cement And Aggregates

Cement manufacturing process & what is cement made of, it can be discussed conveniently under two headings: Selection of Raw materials and manufacturing methods. Raw Materials of Cement. Most important raw materials (what is cement made of) required in the manufacture of Portland Cement are: Limestone, Clay, Gypsum, Fuel, and Water (in wet method).

process in manufacturing cement and aggregates

Cement Manufacturing Process - Civil Engineering Blog. Aug 27, 2015· Cement Manufacturing Process August 27, 2015 S. C. Rangwala Cement, Construction Material 0 The entire manufacturing process in a modern plant is now controlled through a microprocessor based programmable logic control system to maintain uniform quality of cement and a high …

Process In Manufacturing Cement And Aggregates

Process In Manufacturing Cement And Aggregates. We are a large-scale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

process in manufacturing cement and aggregates

Aggregates - Portland Cement Association. Aggregates are inert granular materials such as sand gravel or crushed stone that along with water and portland cement are an essential ingredient in concrete. Get Price; Manufacturing process Lafarge in South Africa - Cement . From the lilimingne quarry to the delivery of the end product follow every ...

Process In Manufacturing Cement And Aggregates

process in manufacturing cement and aggregates,Our company is a large-scale heavy enterprise that taking heavy mining machinery manufactory as main products and integrated with scientific research, production, and marketing. We are concentrating on producing and selling machines such as jaw crusher, cone crusher, hammer crusher, ball mill, sand maker, mobile …

What is the manufacturing process of cement? - …

Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement ki...

Cement: Materials and manufacturing process

• Chalk is porous and often has high moisture content that leads it to its use in the ‘semi-dry/wet’ manufacturing process of making cement. This particular process represents some 16% of total production. Shale • Shale is a pure sedimentary rock made of very fine silt, clay and quarz. Shale falls in the category of mudstones.

Manufacturing process | Lafarge - Cement, …

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km.

Manufacturing process | Lafarge in Kenya - …

From the limestone quarry to the delivery of the end product, follow every step in the cement manufacturing process. Step 1: Extraction of raw materials The raw materials needed to produce cement (calcium carbonate, silica, alumina and iron ore) are generally extracted from limestone rock, chalk, clayey schist or clay.

aggregates manufacturing process - smc0495.nl

Aggregates manufacturing process PPT. 15-Jun-2012 – XSM supply Mining and construction equipment for mineral handling. The crushing ... quarry process calculator - Coal Crusher . This variability can arise at all stages of the cement manufacturing process – quarry, raw milling, … The results from the Variability Calculator are indicative ...

Manufacturing of Portland Cement – Process and …

The manufacture of Portland cement is a complex process and done in the following steps: grinding the raw materials, mixing them in certain proportions depending upon their purity and composition, and burning them to sintering in a kiln at a temperature of about 1350 to 1500 ⁰C. During this process, these materials partially fuse to form nodular shaped clinker by broking of …

The Cement Manufacturing Process - Advancing …

Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kiln.

What is the process of manufacturing concrete? - …

Manufacturing Process A good quality concrete is essentially a homogeneous mixture of cement, coarse and fine aggregates and water which consolidates into a hard mass due to stone action between the cement and water. Concrete: Manufacturing Pro...

Aggregates - Portland Cement Association

Aggregates are inert granular materials such as sand, gravel, or crushed stone that, along with water and portland cement, are an essential ingredient in concrete. For a good concrete mix, aggregates need to be clean, hard, strong particles free of absorbed chemicals or coatings of clay and other fine materials that could cause the deterioration of concrete.

Manufacturing process of cement. | vin civilworld

Cement is considered as the most significant substance used in construction which acts as a binder which can adheres the materials together. Cement is a hydraulic binder when mixed with water and sand transforms into mortar and when mixed with water and aggregates converts to concrete which can be used for a number of applications.…

Describe The Process Of Manufacturing Aggregates

describe the manufacturing process of coarse aggregate. describe the manufacturing process of coarse … material specification for aggregates base, 1010 c coarse aggregate test data form 1010.01 scope thi s speci ficati ...

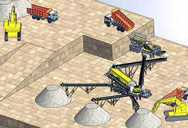

The Aggregate Manufacturing Process | General …

Aggregates are important because of the qualities they possess such as strength, shape, size, texture, bulk, abrasion ability or resistance, medicinal, etc. For more than 50 years, General Kinematics has provided innovative vibratory equipment that is essential in the mining and aggregate manufacturing process. A World of Minerals

Manufacturing process | Lafarge in South Africa - …

Water plus cement plus aggregates. The formula seems simple, but the reality of concrete manufacturing is far more complex. The development of formulas for concrete requires very advanced scientific skills. The quality of the cement and aggregates, the dosage and the proportions are just some of the variables that influence the properties of ...

Manufacturing process | Lafarge - Cement, …

Manufacturing process In theory, producing aggregates simply involves crushing rock. In practice, it is much more complex, as standardized sizes and homogenous aggregates …