What is slag cement

Slag cement is a hydraulic cement formed when granulated blast furnace slag (GGBFS) is ground to suitable fineness and is used to replace a portion of portland cement. It is a recovered industrial by-product of an iron blast furnace.

Mills for cement and granulated blast-furnace slag Gebr ...

Grinding of cement and/or granulated blast-furnace slag – Material separation in the filter The cement components are ground, dried, and classified in the Pfeiffer vertical roller mill. Moist feed materials can be fed to the mill separately from warm and dry feed materials.

Cement And Slag Grinding- ALUNETH Mining machine

Multicem slag cement is produced by grinding gbfs a byproduct of steel production and can be added in the production of concrete and cement multicem slag cement provides strength durability improved finish and consistent performance in concrete and can be used at higher replacement rates than other scms reducing the overall carbon

Grinding plant - Fives in Cement | Minerals

Titan/Beni Suef Cement Co (Egypt) - Cement grinding plant with B-mill; QNCC (Qatar) - Raw meal and cement grinding plants with B-mill; Cementos Moctezuma (Mexico) - Raw meal and cement grinding plants with FCB Horomill® Jingye (China) - Steel slag grinding plants with FCB Horomill®

New slag cement grinding unit to be set up in Houston

New slag cement grinding unit to be set up in Houston. 28 March 2019. Charah ® Solutions Inc has announced that it will use its patented grinding technology in a new facility to grind granulated blast furnace slag (GBFS) for supplementary cementitious materials. The unit will be located at Watcos Greens Port Industrial Terminal (GPIT) on the Houston ship channel and is expected to be operational …

Our vertical roller mill offers optimum raw, cement and ...

Our OK Mill grinding solution skilfully comminutes raw material, cement and slag. You can easily adjust it to grind any feed material and produce multiple cement types in the same mill. Due to its highly effective drying performance, the OK Mill is the natural choice for grinding blended cements with one or …

Fineness Effect on Pozzolanic Activity of Cu-Ni Slag in ...

Cement paste and cemented tailing backfill samples that without or contain Cu-Ni slag with various grinding times were made and cured at 20°C for 7, 28, and 150 days. Mechanical test and microstructural analyses are performed. In general, the pozzolanic activity of Cu-Ni slag increases with the fineness of …

slag cement grinding equipment - boerenlandwandelen.nl

Our machines and processes for the cement and granulated blast-furnace slag industry. Grinding of cement and/or granulated blast-furnace slag – Material separation in the filter. The cement components are ground, dried, and classified in the Pfeiffer vertical roller mill. Moist feed materials can be fed to the mill separately from warm and...

Slag Cement Benefits and Use in Concrete - Slag Cement News

Slag cement is a hydraulic cement formed when granulated blast furnace slag (GGBFS) is ground to suitable fineness and is used to replace a portion of portland cement. It is a recovered industrial by-product of an iron blast furnace.

Modular and portable grinding station Plug and Grind ...

25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUG&GRIND modular and portable grinding stations …

Portland cement - Wikipedia

As with type IV, type V Portland cement has mainly been supplanted by the use of ordinary cement with added ground granulated blast furnace slag or tertiary blended cements containing slag and fly ash.

Cement Grinding Plant,Concrete Grinding Plant,China ...

The cement grinding plant mainly used in crushing and preheating of raw materials, and grinding and packaging of cement. And it is mainly applied to deal with industrial solid wastes like slag, coal ash, coal gangues, and so on. Therefore, it contributes great to the environment protection industry.

More than 400 vertical roller mills for cement and ...

The grinding of clinker and cement and of granulated blast furnace slag and slag in vertical air-swept grinding mills dates back to Ernst Curt Loesche’s invention. In 1927, he applied for a patent for the world’s first spring-loaded air-swept mill – the beginning of the triumph that is Loesche vertical roller mills.

19 Types of cement – Properties and Uses in Construction ...

This cement is prepared by intimately grinding Portland cement clinker and ground granulated blast furnace (GGBF) slag with the addition of gypsum and permitted additives. and the proportion of slag should not be less than 25% and not more than 65% of Portland slag cement.

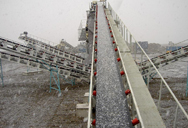

Slag Grinding Plant

As a new type of high performance concrete admixture, ground granulated blast furnace slag (GGBS or GGBFS) has all kinds of performance advantages about improving concrete compressive resistance, tensile resistance, sheared resistance and bended resistance.

Charah Solutions Opens First Facility Using New Grinding ...

MultiCem slag cement is produced by grinding GBFS, a byproduct of steel production, and can be added in the production of concrete and cement.