Feed Size VS Ball Size - Grinding & Classification ...

To participate in the 911Metallurgist Forums, be sure to JOIN & LOGIN Use Add New Topic to ask a New Question/Discussion about Grinding. OR Select a Topic that Interests you. Use Add Reply = to Reply/Participate in a Topic/Discussion (most frequent). Using Add Reply allows you to Attach Images or PDF files and provide a more complete input. Use Add Comment = to comment on someone else’s ...

Calculate and Select Ball Mill Ball Size for …

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize “just in case”. Well, this safety factor can cost you much in recovery and/or mill liner wear and ...

Ball Mills - an overview | ScienceDirect Topics

In general, ball mills can be operated either wet or dry and are capable of producing products in the order of 100 μm. This represents reduction ratios of as great as 100. Very large tonnages can be ground with these ball mills because they are very effective material handling devices. Ball mills are rated by power rather than capacity. Today, the largest ball mill in operation is 8.53 m diameter and 13.41 m …

How Coarse can Ball Mill Feed be - Grinding ...

A quick check of the Rowland optimum feed size for this ball mill is between 3 and 4 mm; operating either circuit you describe will be at least 15% inefficient compared a more conventional ball mill feed size. The screen doesnt matter in terms of energy efficiency; only more crushing (or a small rod mill) that will improve the energy efficiency. I doubt the opex benefit of energy efficiency will matter given the capex …

Ball Mill - an overview | ScienceDirect Topics

Ball mills give a controlled final grind and produce flotation feed of a uniform size. Ball mills tumble iron or steel balls with the ore. The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.-% ore and 25% steel.

Ball mill - Wikipedia

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering.It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical

How can one select ball size in ball milling and …

Ball size depends on initial size of charge and ranges from 10mm-150mm dia. For particular material and initial size the ball size must be optimized. Please refer the link below and see if it works...

Ball Mill Design/Power Calculation

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of circuit open/closed ...

Optimization of mill performance by using

The mill and all feed streams should be stopped simultaneously but, often, they are stopped around about the same time. Slurry could still be pumped out of the mill during a few rotations. The accuracy of the measurement could suffer from the procedure that is followed by the operator. Mill power Usually, plant operators use mill power readings as an indicator of ball filling degree and, often ...

Top 5 product-specific milling technologies used …

Ball mills for super-fine calcium carbonate Ball mill classifier systems have been improved over time and are now capable of achieving much finer products. In the past, a particle size with a D97 of 10 microns was only possible. Now particle sizes down to a D97 of less than 3.5 microns can be achieved, with a D50 in the range of 1.5 microns.

mining equipment ball milling machine e - …

Wet Grid Ball Mill. Capacity: 0.5-500TPH Feed Size: ≤25 mm.Grid ball millis widely used in smashing all kinds of ores and other materials, ore dressing and national economic departments like building and stone industries etc. The size of ore shall not exceed 65mm and the best feed size is under 6mm. The effect in this stone is better than coarse grinding.

ball mill design for 100 kg feed - haushueten …

ball mill design for 100 kg feed. energy consume in ball mill 200 kg hr pharma grade. ball mill design for 100 kg feed . SAG ball mill energy More Info EMAXHigh Energy Ball MillRetsch. The Emax is an entirely new type of ball mill for high energy unrivaled speed of 2000 min-1 and the optimized jar design. Feed material See More . Get Price; The grinding balls bulk weight in fully unloaded mill ...

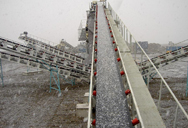

dry ball mill feed size - sameaworkshop.co.za

dry ball mill feed size. Home; dry ball mill feed size ; Get Price Here.... Ball Mill. Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two… Get Price Here.... Belt Conveyor. ASM delivers the world’s most comprehensive range of Heavy-duty conveyor belts. Base on more than 30… Get Price Here.... BWZ Heavy Duty Apron Feeder. BWZ series ...