volume loading in cement ball mill - …

Raw Cement Ball Mill Volume Loading Formula. We are a large-scale manufacturer specializing in producing various mining machines including different types of sand and gravel equipment, milling equipment, mineral processing equipment and building materials equipment.

Working principle of Ball Mill /ball cement milling ...

03-03-2015 · Ball mill is an efficient tool for grinding many materials into fine powder. The Ball Mill is used to grind many kinds of mine and other materials, or to select the mine. It is widely used in ...

media cement ball mill process calculation

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

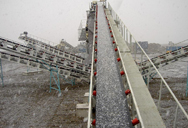

Ball loader | Magotteaux

Save time in a safe manner The Magotteaux ball loading machine enables to load the grinding media into a tube mill in a very fast (15-25 tph) and safe way. The machine is operated by 1 worker and increases the operational safety The loading speed significantly reduces the mill downtime and saves a substantial amount of time and money

Cement mill - Wikipedia

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL …

SHAPES ON BALL MILL PERFORMANCE ... Comminution is an important process in mineral processing, power plants, cement production and pharmaceutical industries. ... Load behaviour, mill power and breakage as affected by media shapes were studied in a pilot laboratory mill.

Ball Mills - an overview | ScienceDirect Topics

Conical Ball Mills differ in mill body construction, ... The tumbling balls capture the particles in ball/ball or ball/liner events and load them to the point of fracture. ... not least because the specific power consumption of vertical mills is about 30% less than that of ball mills and for finely ground cement …

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL …

4. MILL LOAD CONTROL- LATEST CONCEPT FOR CEMENT MILL OPTIMISATION 4.1 Concept M/s Holderbank Engineering, Canada has developed a control strategy for ball mills which can maintain a mill production near optimum, with little operator intervention. …

Ball Mill Design/Power Calculation

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of circuit open/closed ...

Mill Bolting

The mill manufacturer specifies a load which is designed to be the optimum load applied to the bolts to hold the mill together for its entire life, which can be in excess of 20 years, some mill manufacturers specify an elongation, unfortunately they usually specify a torque figure which should in a best case produce the correct elongation, but rarely does.

Calculate and Select Ball Mill Ball Size for Optimum …

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do. Often, the ball used in ball mills is oversize “just in case”. Well, this safety factor can cost you much in recovery and/or mill liner wear and ...

Cement Ball Mill

Overview. The ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores.

Ball mill - Wikipedia

24-07-2004 · The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of ferrous and non-ferrous metals. The ball mill can grind ores and other materials either wet or dry.

CALCULATION OF BALL MILL GRINDING …

08-03-2013 · calculation of ball mill grinding efficiency. dear experts . please tell me how to calculate the grinding efficiency of a closed ckt & open ckt ball mill. in literatures it is written that the grinding efficiency of ball mill is very less [less than 10%]. please expalin in a …

Optimization of mill performance by using

Optimization of mill performance by using online ball and pulp measurements by B. Clermont* and B. de Haas* Synopsis Ball mills are usually the largest consumers of energy within a mineral concentrator. Comminution is responsible for 50% of the total mineral processing cost. In today’s global markets, expanding mining groups are trying

3D Animation Demo & working site of Ball Mill - …

12-11-2014 · Offical website:【http://www.bailingmachinery.com/】 Alibaba website:【http://zzbailing.en.alibaba.com/】 Product webpage:【http://www.bailingmachinery.com/produc...

Analysis of ball mill grinding operation using mill …

01-03-2014 · Thus, a small ball load and a low mill speed are preferable from the point of view of variation in the specific energy consumption with particle load. However, in doing so one has to take in to account the mill production rate also. Reasonably high levels of ball load and mill speed are required to maintain a high production rate.

Cement Equipment,Cement Machinery …

China Sunrise Machinery (CSM-cement production line) is a professional cement equipment manufacturing enterprise,Five types of the products have get European CE certification, meanwhile it owns about 30 patented products &high-tech products. The main products are cement production line including:tube mill,rotary kiln,roller press,vertical mill, rotary dryer,suspension preheater.

Ball Mill,Tubing Mill,ball grinder,globe mill for sale ...

Tubing Mill,ball grinder,globe mill for sale, Cement Mill, Raw Mill, CChina Sunlike Machinery is a leading tube mill of cement production line. We are a professional Ball Mill Manufacturer & …