working principle of paddle feeder - …

Working Principle Paddle Feeder. Working principle: Double shaft paddle mixer is a batch mixer with two counterrotating shaft that are equipped with ten paddles, theyConfiguration 1: vacuum feeder, production silo under the mixer, and packer under silo Configuration 2: manually feed with the folk lift, bulkbag packer under the mixer.

Paddle Feeder / Rotary Plough feeder | Conveyor …

Paddle drive of paddle feeder consists of a hydraulic motor with power pack and planetary gear box.Output shaft of the planetary gear box connects the paddle blade . To protect against possible over loading an effector actuating relay is provided on the output shaft of the planetary gear box.A sensing prob fitted on the output shaft gives pulse signal to the proximatery switch. This pulse count , …

working principle of paddle feeder - rndi.it

The Working Principle of a Rotary Tablet Press Machine ,A rotary tablet press machine is one of the most popular types of tablet compression machin Normally, we use this machine for high production of tablets such as pharmaceutical industri Even though there are different series of tableting machines, the working principle still remains the same In this article, I am going to focus on the ...

Filling the Paddle Feeder - YouTube

26.12.2015 · Filling the Paddle Feeder Dylan McGarvey. Loading... Unsubscribe from Dylan McGarvey? ... vibrating feeder working principle - Duration: 0:34. Mining machinery/Stone Crusher 24,289 views. 0:34 ...

Working Principle of Paddle Wheel Flow Meters ...

Working Principle of Paddle Wheel Flow Meters Paddle wheel flow meters consist of three primary components: the paddle wheel sensor, the pipe fitting and the display/controller. The paddle wheel sensor consists of a freely rotating wheel or impeller with embedded magnets which is perpendicular to the flow and will rotate when inserted in the flowing medium.

ELECON Paddle Feeder | Elecon

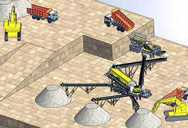

Rotary plow feeders are most useful for handling materials that are sluggish, tend to interlock or mat and thereby arch over restricted openings. They are usually mounted under the bottom of bins and hoppers and are specially designed to prevent bridging or arching of material. A rotating set of plows push material toward a discharge opening .In recent times Paddle Feeders have been very ...

A Enterprise Material Handled, Capacity & Rotor Diameter ...

Feeder consists of a paddle wheel, called “Rotor”, having six curved arms revolving on a vertical axis that sweep the stored material from the shelf on to a Belt Conveyor. The plough mechanism is transported on to a heavy duty self propelled wheeled frame, called “carriage” that travels on rails mounted either on a canopy of the bunker or on the beams supported on the floor of the ...

Coal at paddle feeder in Power plant - YouTube

12.06.2019 · Coal Unloading in Thermal Power Plant-2. running vibrating feeder, jaw crusher and belt conveyor—URL: www.shveking.net - Duration: 0:50. Veking Heavy Industries Recommended for you

Tablet press Feeders the Science behind - Pharma …

Feeders Reality and Misconceptions Tablet press feeders are critical part of tablet press. The article focuses to remove common misconceptions Feeders are classified into two types Force Feeders Gravity Feeders Gravity feeders are used in older machines these feeders supply granules to dies using gravity as driving force Force feeders / Power assisted feeders are commonly used in most recent ...

Rotary feeder - Wikipedia

ARF is a variable speed rotary feeder for bulk materials that works in harmony with the natural flow of the material being fed. The ARF, using a rotating member and articulable gate, controls the volume of material flow based on the materials inherent angle of repose. The speed of rotation and the positioning of the articulable gate provides a consistent feed of your material. Drum rotation allows the material …

Coal handling plant

• The Paddle Feeders feed the coal on the conveyor belt from the Track hopper at a controlled rate. The paddle blades projected in the hopper slot scoop the coal from hoppers and discharge it on the conveyor belt running below. • The following points need to be checked before taking any paddle feeder into service. • a) The paddle arms are free from any obstruction. • b) There is no ...

ritesh final project - LinkedIn SlideShare

In case, if one of the paddle feeders is not working than 1 paddle feeder is designed in such a way that it can alone cover up the entire length. There is a limit switch which guides each of the paddle feeders to the centre. Hence, the entire length of the hopper is covered by 2 paddle feeders in full working condition. There are 2 censors installed that guide the paddle feeder in forward as ...

rod mill belt feeder - Caterpillar Heavy Machinery

rod mill belt feeder.Beltconveyor is a highefficiency and continuous transporting equipment And it is mainly used to convey the loose materials and the end products It can form a rhythmic flow transportation line cooperated with the demands of process in production line of each industrial enterprises. More Detail;rod mill belt feeder . Get a Quote Send Message. Hot Products. Ball Mill. details ...

TechnicalDiary500MW-SgTPP | Energy …

TechnicalDiary500MW

Building Materials Equipment - The working …

Rotary Drum Dryer Working Principle Wet material goes into the feeding hopper by belt conveyor or bucket elevator then through the feeder goes into the feed pipe The feed pipe slope is greater than the natural inclination of the materials so that the material can inflow the rotary dryer smoothly

working principle of rotary vacuum dryer - ME …

Working Principle: The drying in a rotary vacuum dryer is a batch operation under vacuum. (PDF) Vacuum Drying: Basics and Application . The reduced pressure by vacuum increases the mass transfer of water between the stone and its surroundings, which lowers the heat needed for rapid drying and procures a high quality product. 作者: Dilip Parikh. Rotary Drum Dryer Working Principle Video. Oct ...

working principle of coal silo vibrating feeder

Working Principle of Three Types Vibrating Feeder The vibrating feeder, also known as vibration feeder, is used to transfer the large size materials and granular … Vibration Feeder Frame body vibrates strongly on the supporting spring along with vibration motor startup, then the material will be driven to slide and throw motion and make ...