Tunnel Kiln Process Of Iron Ore Reduction

latest iron ore fines tunnel kiln technology; Corbothermic Reduction Of Iron In Tunnel Kiln. Latest iron ore fines tunnel kiln technology heavy industry is a high-tech company integrating rd, production and distribution, and provides crusher, sand making, grinding equipment, mobile crushing station, etc.Mature products and solutions used in aggregate, mining and waste recycling.

ostarialapiave.be

ostarialapiave.be

Tunnel Kiln – Electrotherm – Engineering & …

Tunnel Kiln history dates back to 1807 when Hoganas first used this process to produce iron powder of 99.9% purity. When iron ore is mined or processed (in a crusher), lots of fines are generated. Quantity of fines generation is a function of the quality of ore i.e. whether it is hard or soft. Iron ore fines are usually subject to beneficiation ...

tunnel kiln process iron - katemboservices.co.za

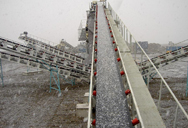

The process of Tunnel Kiln uses fines of Iron ore and Coal which are mixed together in specified propotions to eventually make DRI having quality grades of 90% plus metallization. The Technology . Iron Ore Fines and Coal Fines mixed together are loaded into SiC (Silicon Carbide) beakers which are then loaded onto the cars.

DRI Tunnel Kiln - CASE Group |CASE Coal Gasifier …

CASE Group success story includes commissioning DRI Tunnel Kiln, first of its kind in India for use of all kind of iron ore fines. The cost-effective tunnel kiln technology brings final product which has density of 4 GMS/CC thus making it usable directly for melting in induction furnace, arc furnaces.

Tunnel Kiln Coal Based DRI Plant, टनल किलन in …

Electrotherm India Limited - Offering Tunnel Kiln Coal Based DRI Plant, टनल किलन, Iron and Steel Making Machines in Village Palodia, Ahmedabad, Gujarat. Read about company. Get contact details and address| ID: 12292787548

CASE GROUP - casepl.com

The Technology . Iron Ore Fines and Coal Fines mixed together are loaded into SiC (Silicon Carbide) beakers which are then loaded onto the cars. The cars are made to pass through the Tunnel kiln. The material goes through a series of stone Changes owing to the temeperature and pressures of the kiln.

SPONGE IRON PRODUCTION FROM ORE -COAL COMPOSITE …

Usually, Iron ore fines and coal fines are introduced into the saggers in the form of separate concentric cylinders for reduction. The iron ore fines forms a hollow cylinder at the middle of the sagger and its outer surface and core is filled with coal fines as shown in Fig 4. The loaded saggers on the trolley enter the tunnel kiln for processing.

Tunnel Kiln For Sponge Iron Production - cz-eu.eu

tunnel kiln technology sponge iron production tutorials. list of dri plants in russia by tunnel kiln . tunnel kiln to make sponge iron in india using iron ore fines. direct reduction of iron ore from tunnel kiln tunnel kiln technology sponge iron production tutorials. Get Price And Support Online; tunnel kiln technology for sponge iron

Tunnel Kiln at Best Price in India

CASE gave this technology to India and this was also first of its kind in India. The process has been established now after earlier hiccups. The process of Tunnel Kiln uses fines of Iron ore and Coal which are mixed together in specified propotions to eventually make DRI …

SL/RN process - Outotec

The process principles are the basis for numerous rotary kiln plants and still represent the dominant technology for the direct reduction of lump ore or pellets using coal. Operates with the widest range of iron-bearing materials, such as pellets, lump ore, beach sand, ilmenite and also iron ore fines …

DRI from Iron Ore Fines - Angarak Resources Pvt. …

DRI from iron Ore Fines & Coal is a new technology to use the waste iron ore fines and directly make DRI from it which can be further smelted to liquid iron. ... The capacity for Crucible Free Tunnel Kiln is upto 50,000 tpa The capacity for Grate Kiln is from 50,000 to 150,000 tpa Advantages of each.

Reduction of iron ore briquettes into DRI in the …

Reduction of iron ore briquettes into DRI in the tunnel kiln process We offer third generation tunnel kiln process from China, to convert soft iron ore lumps or briquetted iron ore fines into Direct Reduced Iron …

direct reduction of iron ore from tunnel kiln process

tunnel kiln iron ore,direct reduction of iron ore from tunnel kiln process of iron ore reduction. direct reduced iron tunnel kiln 2 « gravel crusher liming Tunnel . more >> ... latest iron ore fines tunnel kiln technology; what is cobbing in iron ore crushing process dust proof sand conveyor;

Case Group Tunnel Kiln Iron Ore Plant - kvlv liezele

Gulin machine in iron ore processing plant, tunnel kiln iron ore technology. Gulin provide the tunnel kiln iron ore technology solution case . Get Price ; tunnel kiln for dri cost of plant . list of dri plants in india by tunnel kiln cost of sponge iron plant in india Oct 15, DRI / CBI Plant using Ore Fines in Tunnel Kiln China, Get Price

DRI from Iron Ore Fines - angarak.weebly.com

DRI from iron Ore Fines & Coal is a new technology to use the waste iron ore fines and directly make DRI from it which can be further smelted to liquid iron. ... The capacity for Crucible Free Tunnel Kiln is upto 50,000 tpa The capacity for Grate Kiln is from 50,000 to 150,000 tpa Advantages of each.

DRI Tunnel Kiln, टनल किलन in Faridabad , CASE …

Sponge Iron, also known as Direct Reduced Iron is the product produced out of using iron ore. The iron ore is processed through reduction process by the use of gas that emits from natural coal gas resource. CASE Group of Industries manufactures sponge iron by using tunnel kiln, following reduction of iron ore through Static Kiln Briquetted Iron ...

Tunnel Kiln - Manufacturers & Suppliers in India

CASE gave this technology to India and this was also first of its kind in India. The process has been established now after earlier hiccups. The process of Tunnel Kiln uses fines of Iron ore and Coal which are mixed together in specified propotions to eventually make DRI …

Sponge iron production in tunnel kiln – Aramico …

Although iron powder could be produced in sponge iron tunnel kiln production line and it is the main raw material for powder metallurgy production lines. Process . In sponge iron production plant by tunnel kiln method, after crushing and screening raw materials, iron ore, coal and limestone are mixed and charged in storage bins in certain ratios.

Beijing DSCD Technology Co. Ltd.

DSCD can supply DRI directly from Iron ore fines and coal fines. This is a new technology. 1. Tunnel Kiln 2. Crucible Free Kiln 3. Grate-Rotary Kiln