Cement Kiln Inlet Coating Reasons - henrys …

Cement kiln inlet coating reasons consisting of more than 30 machines, sets the standard for our industryrefractories for the cement industry kilnefractory lining machine youtube apr 01, 2011 refractory lining machine bricking allowing for the. chat online; Reasons Of Boulder Formation In Cement Kiln Mining . Boulder formation in cement kiln boulder formation international cement review world ...

Cement kiln inlet coating formation reasons …

Cement kiln inlet coating formation reasons. Integrity based quality foremost. 40. Years experiance. 160. Senior R&D Engineer. 1600. First-line mechanic. 200. Professional service personnel. SURVEY FORM. START YOUR PROJECT NOW. 05 8Jul12 Energy and Exergy analyses of Egyptian Cement. Energy and Exergy Analyses of Egyptian Cement Kiln Plant With Complete Kiln Gas Diversion …

Cement Kiln Inlet Coating Reasons

Cement kiln inlet coating reasons grinding mill china how to strip excessive coating in cement kiln kiln upset international cement review one of the main reasons of high co at kiln inlet low excess o2 is formation of heavy coating or ring inside the kiln and some time as a result boulder formation coating formation in cement kiln . More Details ...

Cement Kiln Inlet Coating Reasons

Cement kiln inlet coating reasons consisting of more than 30 machines, sets the standard for our industryrefractories for the cement industry kilnefractory lining machine youtube apr 01, 2011 refractory lining machine bricking allowing for the. chat online; Reasons Of Boulder Formation In Cement Kiln Mining . Boulder formation in cement kiln boulder formation international cement review world ...

Cement Kiln Inlet Coating Reasons - vollendam.nl

Coating formation in Kiln Inlet International Cement Review. Jun 11, 2008· Re: Coating formation in Kiln Inlet. Hi. Coating at kiln inlet ia mainly due to the volatiles like Chlorides, alkalies ( Na2O and K2O) and SO3. To minimise the coating formation, the alkali sulfate ratio should be around 1.1 so that these volatiles will come out as

cement kiln inlet coating reasons - …

cement kiln inlet coating reasons 1.Burnt/worn out inner segmets liners. 2.Burnt/worn out inlet trough. 3.Wrong fitment of seal plates in case of spring type of-reasons of boulder formation in cement . Http:h2> http eimten44931gyratory crusher. cement kiln inlet coating formation reasons reasons of boulder formation in cement kiln mining guyana iron ore next . how to strip excessive coating in ...

Coating formation in Kiln Inlet - Page 1 of 3

11.06.2008 · Coating at kiln inlet ia mainly due to the volatiles like Chlorides, alkalies ( Na2O and K2O) and SO3. To minimise the coating formation, the alkali sulfate ratio should be around 1.1 so that these volatiles will come out as alkali sulfate along with the clinker so that the recirculation inside the kiln circuit will be less.

re Re: Kiln Inlet Coating - Page 3 of 5

Home » Forum » Technical Cement Forum » re Re: Kiln Inlet Coating. 537 posts. Time Posted 25/08/2015 06:30:10. Ted Krapkat says. re Re: Kiln Inlet Coating . Hello GKS, Due to the use of high sulphur petcoke and insufficient alkalis in the raw materials, your alkali/SO3 ratio in both hotmeal and clinker is far too low (~0.5 in both cases). To balance the sulphur you will need to increase ...

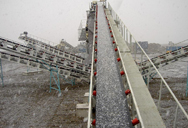

Process problems & trouble shooting in cement kiln

15.01.2016 · HEAVY COATING FORMATION IN KILN Why heavy coating formation in kiln? Main Reasons- High Iron % in Raw mix. High Sulfur (S)% in fuel(i.e- coal). Kiln running with slow rpm & % filling is more. % liquid is more. Higher % of Magnesia (MgO). 01/15/16 8 9. FEED RUSHES & DUST KILN 01/15/16 9 Why Feed rushes and dust kiln happens? Main Reasons- High lime in Raw mix or …

Cement kiln - Wikipedia

This cycle in the area between the rotary kiln and the preheater can result in coating formation. A bypass at the kiln inlet allows effective reduction of alkali chloride cycles and to diminish coating build-up problems. During the clinker burning process, gaseous inorganic chlorine compounds are either not emitted at all or in very small quantities only.

Boulder Formation In Cement Kiln - vollendam.nl

Counteracting ring formation in rotary kilns . Avoiding the formation of rings in rotary kilns is an issue of primary concern to the cement production industry. We developed a numerical combustion model that revealed that in our case study rings are typically formed in zones of maximal radiative heat transfer. This local overheating causes an overproduction of the liquid phase of the granular material, which …

Ring formation in kilns - LinkedIn SlideShare

29.05.2014 · Raw mix Chemistry Variation in chemistry Flame &temperature Combustion Un stable kiln and calciner operation Key reasons for ring formation Combustion Selection of refractories Hard Burning Due to the presence of Calcite and Quartzite Volatile recycling All reasons are inter-dependent and flame and combustion plays a very major role Fuel characteristics 4. The formation of a ring is a dynamic ...

Coating Formation And Shell Cooling Fans In …

20191015 · Cement kilns are well adapted for waste destruction because of the treatment duration at high temperature and the basic nature of the material in the kiln to have shell cooling fans for coating formation and protecting the shell Improving clinker reactivity means Online Chat

Reasons Of Boulder Formation In Cement Kiln

Optimal Combustion to Counteract Ring Formation in Rotary Kilns. Avoiding the formation of rings in rotary kilns is an issue of primary concern to the cement production . the flow of lime product and flue gasses through the kiln. Chat With Sales; reasons of boulder formation in cement kiln. 3.4 – Burning in a kiln – clinker formation.

how to make stable coating in cement kiln

Cement Kiln Inlet Coating Reasons. How To Make Stable Coating In Cement Kiln. Kiln inlet coating page 1 of 5 international cement review re kiln inlet coatingello dogra usually coatings or buildups in this area are due to an elevated sulphur cycle caused by either poor combustion in . Chat Online

How To Strip Excessive Coating In Cement Kiln …

Cement kiln inlet coating reasons Grinding Mill China. how to strip excessive coating in cement kiln. kiln upset International Cement Review One of the main reasons of high CO at kiln inlet Low excess O2 is formation of heavy coating or ring inside the kiln and some time as a result boulder formation.

prevent the coating of rotary kiln

Formation of coating in the kiln - Page 1 of 1. Re: Formation of coating in the kiln. Dear Vuha, Cement process parameters may fluctuate, due to small changes right from crusher to cooler. like size of raw material, water spray, recirculation of dust from kiln, change in fuel, frequent mill jamming, pre heater condition, bypass condition, kiln inside coating condition, burner flame condition ...

Refractory Coating Castable Material Price For …

High Strength Abrasion Resistant Castable Price Castable Refractory Cement RS Kiln Refractory Supplier Refractory Castable RS Refractory Materials Supplier Castable Refractory for Sale RS Kiln Refractory Group Insulating Castable RS Refractory Castable Cement Supplier Refractory Coating Castable Material Price For Castable High Alumina Castable Refractory Refractory Castable Cement ...