LEADING THE WAY IN MINING SHOVEL PRODUCTIVITY

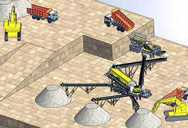

Optimization of the fleet per shovel productivity in surface mining Oct 4 2017 in surface mining is by truck and shovel combination that may cost several millions of dollars but as productivity increases over time the cost Productivity of an excavator and dump truck during stripping and ore increase the productivity of dumpers in mining increase the productivity of dumpers in mining

Productivity Considerations for Shovels and Excavators

The shovel is offline 3.5% of the time and it propels to a new digging position 3.1% of the time. Siemens builds drive systems for electric shovels. The cycle time for an electric shovel differs slightly from a hydraulic excavator. For an electric shovel with a 70º swing radius, the cycle time averages 33.8 seconds, according to Koellner.

Optimization of the fleet per shovel productivity in ...

3.1. Calculations of the productivity backhoe excavator In surface mining operations were the daily productivity of the ore to be hauled to the plant has been determined, it is also important to first estimate the productivity of the loader before estimat-ing the productivity of the dump trucks when trying to optimise the fleet due to the following

increase the productivity of dumpers in mining

productivity of mining shovels dumpers effect of equipment utilisation on economics of mining - CiteSeerX. Productivity is the output of the equipment per unit time. dumper system used in the mine is capable of giving an output of 226 tons per hour, if two dumpers.

productivity of mining shovels dumpers - deboomgaardier.be

shovel dumper combination. productivity of mining shovels dumpers Mining Ciros crushing equipment is designed to achieve maximum productivity and high reduction ratio shovel dumper combination in opencast minephp shovel dumper combination,shovel dumper combination sand washing machineModeling for the steady state .

Hydraulic Mining Shovel Lineup | Cat | Caterpillar

Proving its long-term productivity and reliability, the 6090 FS fleet currently averages more than 33,000 operating hours per unit – with one machine already beyond the 100,000 hour benchmark. The 6090 FS is the only hydraulic mining shovel capable of loading 360-tonne (400-ton) ultra class trucks such as the Cat 797 in just four passes.

(PDF) DETERMINATION OF SHOVEL -TRUCK PRODUCTIVITIES IN ...

A variety of mining equipment is used in the mining of oil sands by surface mining. This includes bucket wheel excavators, draglines, hydraulic shovels and off-highway trucks.

Performance Measurement of Mining Equipments by Utilizing …

Shovels are used in open pit mining as primary loading equipment. Their performance and production controls the total output of operation. Therefore any production loss in shovel causes an increase in total production cost.

Power shovel - Wikipedia

A power shovel (also stripping shovel or front shovel or electric mining shovel or Electric Rope Shovel) is a bucket-equipped machine, usually electrically powered, used for digging and loading earth or fragmented rock and for mineral extraction. Power Shovels are a type of rope/cable excavator, where the digging arm is controlled and powered by winches and steel ropes, rather than hydraulics ...

(PDF) Performance Measurement of Mining Equipment

Abstract: Achieving the high production and productivity target is one of the biggest challenges for mining companies, in order to remain competitive in the global market.

increase the productivity of dumpers in mining

3DEXPERIENCE for Mining Productivity & Profitability "To go beyond" mining companies must look to technology as an enabler The 3DEXPERIENCE Solution Rather than ramping up production (more trucks, shovels, mills, etc.) at all cost, mining companies must take a strategic approach using end-to-end software applications to increase productivity and profitability of their ore deposits

Viewpoint Mining Magazine - Cat shovel reliability ...

Cat ® shovel reliability translates to high productivity. When a loading tool goes down on a mine site, production can come to a standstill. Being able to rely on mining shovels and predict when shutdowns may occur is essential to a productive, cost-effective operation.

3 STUDIES ON AVAILABILITY AND UTILISATION OF MINING ...

The production performance of mining equipment depends on its availability and utilization. Hence it is necessary to determine the percentage availability and utilization of machinery with an aim to improve the same.

Taconite | Minnesota DNR

The taconite pieces are scooped up by electric shovels. Each shovel can hold up to 85 tons of rock! The shovels place the taconite into giant dump trucks. These trucks are as big as a house and hold up to 240 tons of taconite. The trucks take the taconite directly to the processing plant, if it is nearby, or to train cars if it is far away.

Improving Productivity with Autonomous Mining | Cat ...

Mine sites that put autonomous mining technologies to work have also experienced a number of other valuable benefits, including increased productivity, higher equipment utilization and less machine damage. In fact, some sites have witnessed speed and efficiency increases that shorten cycle times and increase production by up to 25 percent.

opencast coal mining by shovel dumper and dragline ppt

Performance Of Shovel Dumper Combinationjugendtag Shovel dumper mines pdf shovel dumper combination productivity of mining shovels dumpers Mining Ciros crushing equipment is designed to achieve maximum productivity and high reduction ratio shovel dumper combination in opencast minephp shovel dumper combinationshovel dumper combination sand ...