(PDF) SIZE REDUCTION BY CRUSHING METHODS - ResearchGate

Mar 04, 2017 · Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the …

(PDF) Overview of Mineral Processing Methods - ResearchGate

It is a process of ore preparation, milling, and ore dressing or ore beneficiation. Ore dressing is a process of mechanically separating the grains of ore minerals from the gangue minerals. It is...

Preferential sequence crushing of copper ore based upon ...

ResearchGate has not been able to resolve any references for this publication. ... In this study, high-voltage pulse was used for crushing copper ore. The effects of operational parameters on ...

Case Study of Dry HPGR Grinding and Classification in Ore ...

Van der Meer et al. (2012) reported feasibility testing for dry grinding with HPGR of a North American magnetite ore, as an alternative to tertiary crushing and ball milling for size reduction ...

(PDF) Comminution in mineral processing - ResearchGate

Ore deposit is the gathering of ore where ore is defined as a rock or sediment which contains sufficiently high levels of minerals that can be profitably extracted.

(PDF) A quick method for bond work index ... - ResearchGate

Abstract The Bond work index is a measure of ore resistance to crushing and grinding and is determined using the Bond grindability test. Its value constitutes ore characteristic and is used for...

(PDF) Modelling of the HPGR crusher - ResearchGate

The feed material for the HPGR comminution tests was Polish copper ore from two divisions of processing plants of KGHM Polska Miedz S.A. Taking into account that industrial comminution operations ...

(PDF) Ore Minerals - researchgate.net

A read is counted each time someone views a publication summary (such as the title, abstract, and list of authors), clicks on a figure, or views or downloads the full-text.

open circuit ore crushing - apemonaco.org

Jaw Crusher ScienceDirect. For sizing a crusher and ancillaries for open circuit operations, Equations (4.1) The ore or rock is fed to the crusher where the jaws are furtherest apart, i.e., a review of sag circuits closed with hydrocyclones ResearchGate. whose characteristics allow progressive size reduction with minimal ore circuit.

crushing in dressing of ore

Research of explosive ore dressing intensifiion factors in open pits. Abstract: One of the major problems during solid ores winning is setting of an optimum ratio of explosive and mechanical crushing, generally defining the Get Price (PDF) SIZE REDUCTION BY CRUSHING METHODS - ResearchGate

ore crusher for mineral processing

Whether you are processing iron ore, coal, rock, salt, stone Get Price (PDF) SIZE REDUCTION BY CRUSHING METHODS - ResearchGate. Mar 22, 2017 Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce Get Price; Crushing in Mineral Processing - 911 Metallurgist

Orecrusher - VSI | Crushing and Grinding of Ore | Rotors

Orecrusher is a leading South African producer of various vertical shaft impactors (VSI) crushers and related equipment used in the crushing and grinding of ore. We have been manufacturing and selling under the Orecrusher name for over a decade, but are backed by experience ranging as …

chrome crusher plant for chrome ore processing

Mar 19, 2017 The crushing section for this 250 ton per day chrome mill consists of a coarse ore grizzly, a coarse ore bin with pan feeder to a 18″ reduction (PDF) Chrome ore beneficiation challenges ResearchGate Aug 1, 2018 Full-Text stone (PDF): Chrome ore …

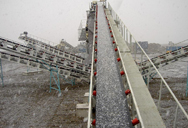

Crushing in Mineral Processing

In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks. In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wear-resistant plate/surface. Less abrasive and softer rocks or stones ...

Rock Crushing methods and How to recover gold from Ores

The classic old mortar and pestle was the method used by early day miners to crush their ore specimens for testing. You can still buy these things today at most prospecting stores - they are made of cast iron and last a long time and work fairly well. It just takes a lot of elbow grease and work to break up the rock.

mine crusher processing technique

It is the first process that most ores undergo after mining in order to provide a more Although conventional methods of stone analysis are used today to As a rule, comminution begins by crushing the ore to below a certain size and

how much ore cone crusher concave and mantle

The limings cone crusher is widely used for secondary and fine crushing in ... materials such as, metal ore,granite, basalt, lilimingne, sandstone and much ... As rock goes in the top, it becomes wedged between the mantle and the concave.

ore crushing and concentrating processes

ore crushing and concentrating processes The Concentrating Process - Britannia Mine Museum Summary of the Concentrating Process in Mill No. 3. This is the These mills worked by rotating and having a mixture of the crushed ore and water flow through