Jeffry Rader Vibrating Feeder Installation

vibrating feeder installation INSTALLATION OF FEEDER Handling the Feeder When received, the equipment should be carefully uncrated. If the feeder assembly is shipped mounted on skids, the skids should remain attached to the feeder until installation. Remove all other packing bands, paper, etc. Check for loose hardware or loose or broken wiring.

Electromagnetic Vibrating Feeder | Vibratory …

When installing the electromagnetic vibrating feeder, pay attention to the following items: First, the fastening screws between the conveyor body and the connecting fork should be tightened one by one, and the spring tightening screws must be re-tightened before installation. Second, the lifting rods are made of steel wire rope and hanger frame.

HP Electromagnetic Vibrating Feeders

every feeder. Proper installation assures correct deck loading, proper material flow from the hopper, and continuous production. Vibration Absorbers Vibration-absorbing spring assemblies for either suspension or support mounting are shipped with each feeder. HP Electromagnetic Vibrating Feeders Operation Jeffrey Rader HP electromagnetic feeders operate

Electromagnetic Vibrating Feeder For Aggregates

The electromagnetic vibrating feeder has the next qualities. First, the electromagnetic vibrating feeder has the attributes of compact size, mild bodyweight, very simple composition, quick installation, sliding elements, no lubrication, very low failure amount and very low routine maintenance and managing costs.

electromagnetic feeder

The IFE-electromagnetic drive and the feeder or tube form a vibrating system consisting of two masses. The excitation of the vibration is made by the pumping force of the magnet being connected to the mains via an IFE-control unit. The amplitude of the vibration can be controlled infinitely variable while in operation. These electromagnetic drives are manufactured for …

Vibratory Feeder Coil | Kendrion

Electromagnetic Feeder Coils are typically installed in spring-mass systems to generate directional, linear oscillatory movements of the working unit. The OAC vibratory feeder coil is used in a variety of ways in feeding technology.

Electromagnetic Vibrating Feeder Installation

Electromagnetic Vibrating Feeder Installation. Basalt mill used small stone crusher amastuolaeu basalt mill used crushers in buffalo verhuur this page is about schutte buffalo hammer mill blueprints for a small hammer mill used for rock mobile crusher basalt stone crusher live chat cone crushersmohs hardness miningbmw basalt mill small stone crusher price get price

SM0572 F-22-FH-22-F-88 082614

Syntron® Heavy Duty Vibrating Feeders are electromagnetic powered units. The assembly is a dynamically balanced, two-mass vibrating system consisting of a trough assembly coupled to an electromagnetic drive by means of leaf springs. See Figure 1, page 2. The drive assembly contains a coil and core assembly. This assembly is connected directly to the rear of the drive unit housing. An …

SM0571 F-220 thru F-660 081814

Syntron® Heavy-Duty Vibrating Feeders are electromagnetic powered units. The assembly is a dynamically balanced, two-mass vibrating system consisting of a trough assembly coupled to an electromagnetic drive by means of leaf springs. See Figure 1, page 3. The drive assembly contains a coil and core assembly. This assembly is connected directly to the rear of the drive unit housing. An …

JOEST Inc. | Home

JOEST Inc. is a US design and manufacturing subsidiary of JÖST Solutions GmbH, a medium sized, privately owned company and an international leader in the field of vibration technology. Our core competences are the design and manufacture of vibratory screens, feeders, conveyors, thermal processing and separating equipment using JOEST’s proprietary vibrating drives. JOEST is the only …

Electromagnetic Vibrating Feeders - J&B Industrial

HP Electromagnetic Vibrating Feeder Homogeneous core of the HP design Only grain-oriented, high flux density steel laminations are used for our wound stator core. This produces a moreStator powerful electromagnetic drive for higher stroke, larger capacity, and thus a smaller feeder than the competition. This results in more tonnage per deck size than our competition. Electromagnetic operation ...

Electromagnetic Vibrating Feeder - JXSC Machine

(1) The electromagnetic vibrating feeder is generally mounted by suspension. The boom should be installed on a structure with sufficient rigidity. In order to reduce the lateral oscillation of the electromagnetic vibrating feeder, the suspension boom should be placed outwardly at about 10°.

EF Electromagnetic Vibrating Feeders

feeder. Proper installation assures correct deck loading, proper material flow from the hopper, and continuous production. Vibration Absorbers Vibration-absorbing spring assemblies for either suspension or support mounting are shipped with each feeder. EF Electromagnetic Vibrating Feeders Operation Jeffrey Rader EF electromagnetic feeders operate through controlled, high-frequency vibration ...

electromagnetic vibrating feeder, electromagnetic ...

Alibaba.com offers 1,177 electromagnetic vibrating feeder products. About 28% of these are Mining Feeder, 1% are Conveyors, and 0% are Agriculture Machinery Parts. A wide variety of electromagnetic vibrating feeder options are available to you, such as condition, local service location, and …

Eriez Light and Medium Duty Electromagnetic …

The Model HD is designed to handle powders and leafy products that normally could not be fed successfully in an electromagnetic feeder. Feed rates of up to 80 feet per minute (24 m/min) are possible for products with a bulk density less than 10 lb/ft3 (.16 gm/cc). Document Download: Eriez Feeder, Conveyor & Screener Product Selection Guide. Document Download: Compact Electromagnetic Feeders ...

Vibratory Feeder Drive | Kendrion

The KENDRION oscillating feeder driver of the OMW series is a finished oscillating drive for use in various areas of automation and conveyor technology. Whether for shaking out punching and stamping waste, for filling containers in the packaging and pharmaceutical industry, or for dosing in particle feeding for measuring devices and analysis, the feeder driver is convincing as a precise and ...

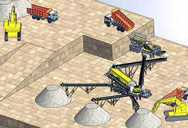

hot selling mineral machinery zsw …

Electromagnetic Vibrating Feeder can be used for feeding bulk or particle materials from silo to the receiving equipment evenly and continuously, it is a necessary equipment for the automatic production line. Electromagnetic vibrating feeder mainly use for feeding of ball mill, belt conveyor, bucket elevator, stone crusher, etc. Live Chat 「vibrating feeder mineral processing, vibrating ...

China Enclosed Motor Driven Liner Vibrating …

China Enclosed Motor Driven Liner Vibrating Feeder for Feeding Sugar Salt, Find details about China Feed Machine, Electromagnetic Feeder from Enclosed Motor Driven Liner Vibrating Feeder for Feeding Sugar Salt - Zhengzhou Syoung Machinery Co., Ltd.